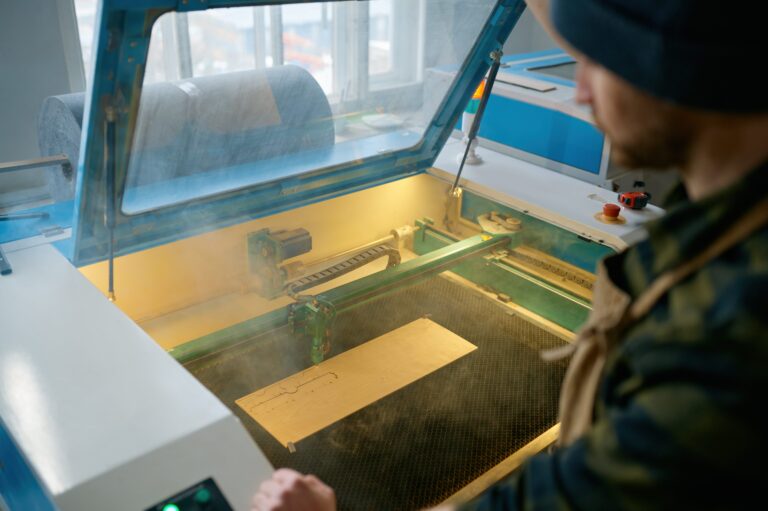

Fiber laser

A fiber laser creates light in a diode-pumped, rare-earth-doped glass fiber (often ytterbium). The same fiber both amplifies and guides the light to the cutting head. There, the beam is focused to a very small point of high energy density. The result is a narrow cutting gap (kerf), high speed and good detail reproduction-especially in thin to medium-thick sheet metal and in reflective metals such as aluminum and copper.