Punching

Complex or simple, you decide...

Our automatic presses punch complex or simple products in metal.

Product features punching

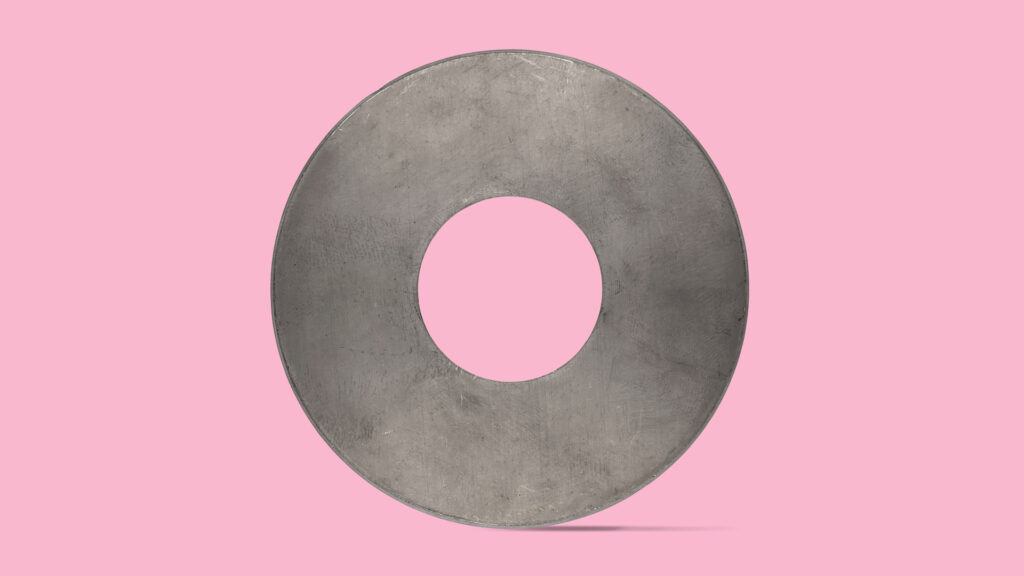

Made of steel, hardenable steel, stainless steel, high strength steel, copper, brass, aluminum

Thicknesses down to 0.10 mm

Up to 1 500 MPa ultimate tensile strength without subsequent hardening

High demands on flatness and tolerance

Contact us

Contact us and we will help you

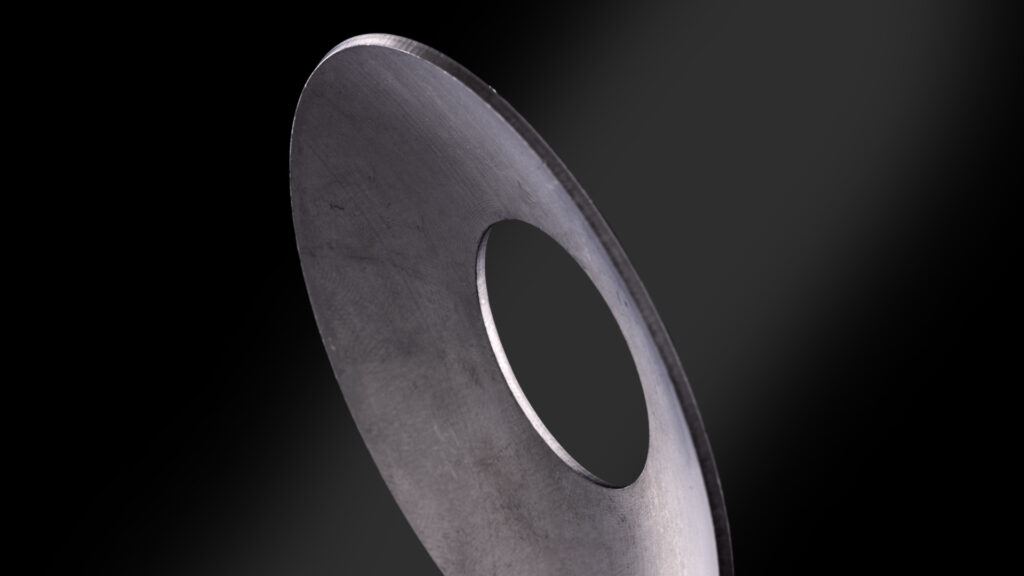

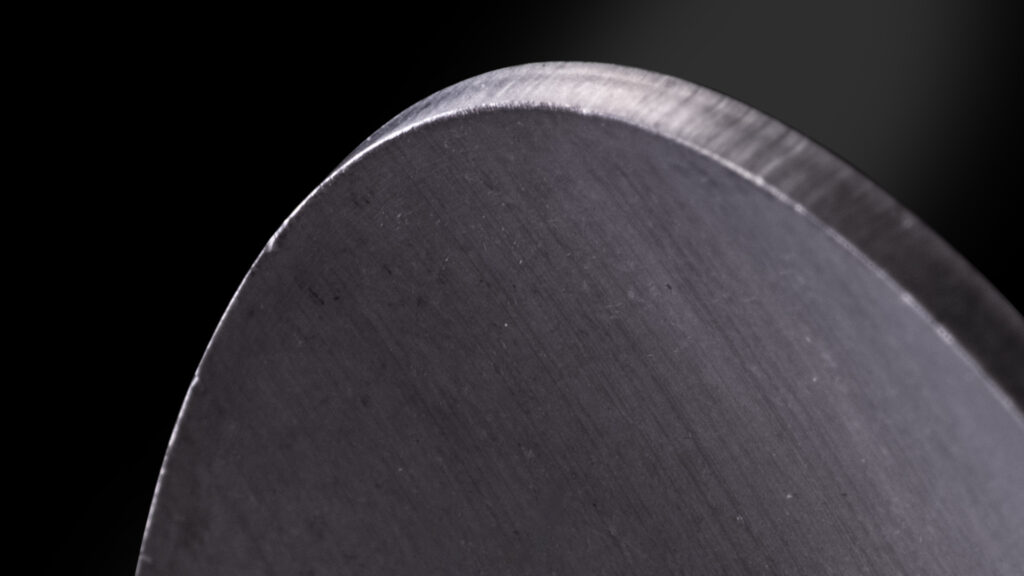

Punching of steel

At Thor Ahlgren, we see steel as a malleable material, like the old masters in the early days of industry. We have embraced the legacy of the early industrial years and combined it with modern technology. At the same time, we have preserved the spirit of hard work and craftsmanship that characterized those times. Through our stamping process, we produce parts that meet customer requirements - from simple to complex geometries.

Why choose Thor Ahlgren?

- Innovation and precision: From prototype to mass production.

- Material diversity: Steel, high-strength steel, stainless steel, copper, brass or aluminum - we handle it all.

- Environmental considerations: Our sustainability strategy is integrated into every step of production. We measure our CO2 footprint and strive for sustainable business and a pleasant working environment.

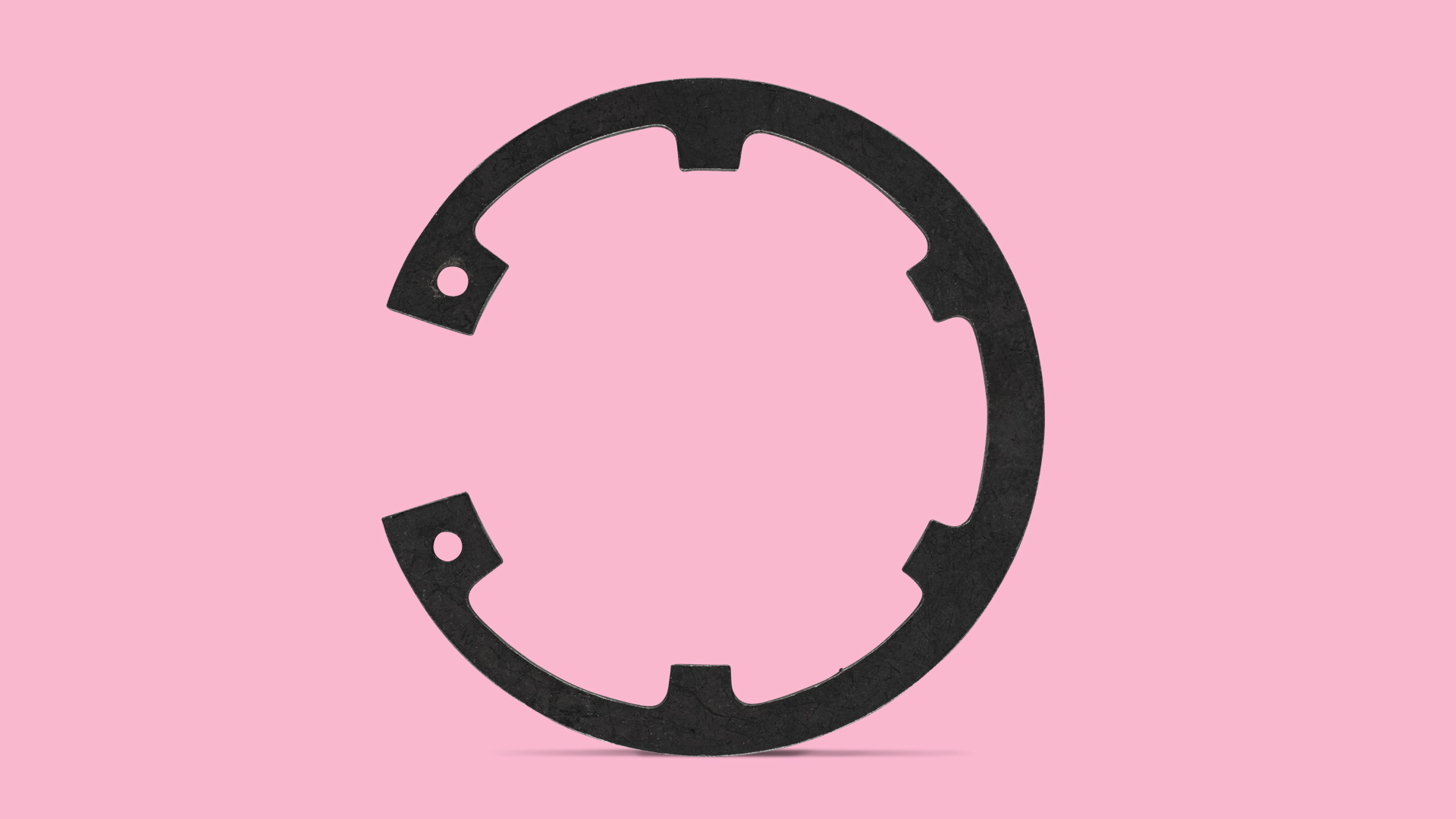

Our punching services

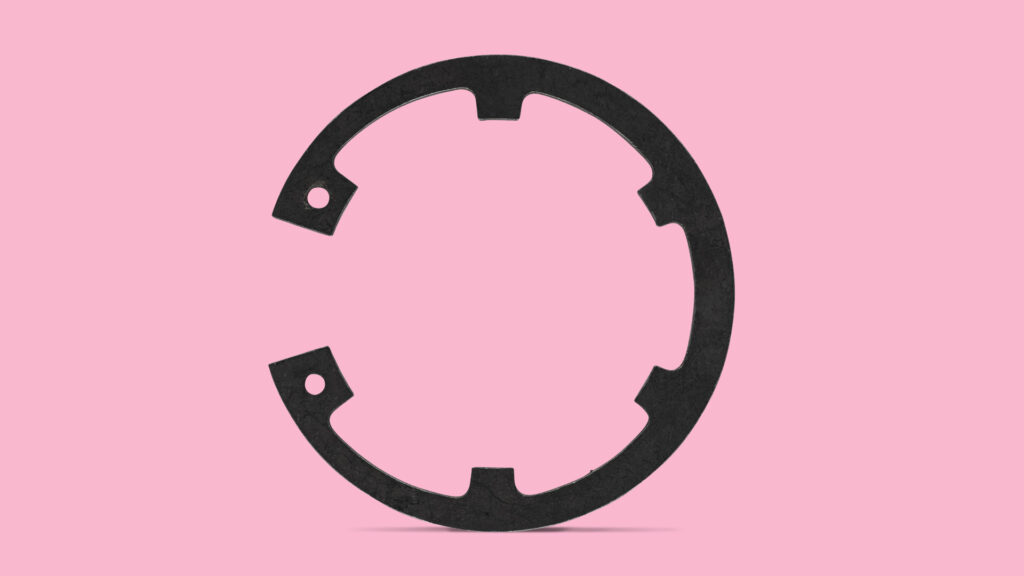

Do you have an item that needs to be punched? We specialize in customizing it to ensure that production is as efficient as possible and according to your specifications. With our machines, we punch and press details with precision in shape, depth and surface. Whether it's a small or large series, we always deliver with the agreed precision

A long history of expertise

Thor Ahlgren builds on a rich tradition in metalworking. With generations of experience, we have refined the art of metal forming. Our history is the foundation for the quality we offer today. We have always valued craftsmanship and precision which is reflected in every item we create.

What is punching?

Die-cutting is a manufacturing process used to cut materials, usually metal, using a die-cutting tool. The process involves using a punch and a die to create specific shapes by applying pressure to the material. Die-cutting is used in many industries, including automotive, electronics and construction

How does die-cutting work?

The process starts with a metal sheet or other material being placed between a punch and a die. As the punch is pressed down through the material, it is cut to the desired shape. The method is used to create complex shapes with high precision and repeatability

Wide range of materials and environmental considerations

We work with a wide range of materials, including different metals and composite materials, to meet different customer needs. Our commitment to sustainability means we also focus on environmentally friendly practices and material choices. By minimizing waste and using recyclable materials, we aim to reduce our environmental impact

Punching techniques and their benefits

Punching is an efficient method for cutting materials. The method offers several advantages:

- High precision: creates accurate and consistent shapes.

- Efficient production: Enables fast production of large volumes.

- Versatility: Can be used on a wide range of materials.

By combining tradition and reliable technology, Thor Ahlgren continues to be a leading player in punching of sheet metal.

How we at Thor Ahlgren work with punching

At Thor Ahlgren, we use reliable stamping equipment and experienced technicians to ensure that every part we produce meets the highest quality standards. We offer customized solutions to meet the specific needs of our customers, whether it is small series or mass production.

Contact us for more information

Want to find out more about how we can help you with your stamping needs? Contact us today to discuss how our combination of tradition, innovation and craftsmanship can contribute to your project.